Precision measurement plays a critical role in modern science, engineering, and manufacturing. Instruments that can detect extremely small changes have become essential across industries. At the heart of this technology is the interferometer, a device that uses light waves to measure tiny distances, vibrations, or surface variations with incredible accuracy. As demand for these instruments grows, professionals are increasingly interested in finding reliable interferometer manufacturers who can deliver equipment that meets strict quality and performance standards.

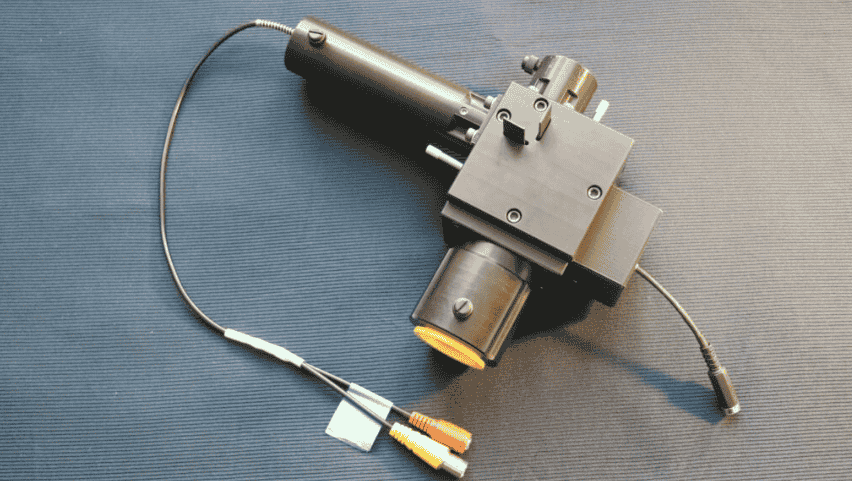

An interferometer might sound complicated, but the basic principle is simple: it splits a beam of light, sends the parts along different paths, and then recombines them to reveal even the smallest differences. Because lasers and optics are involved, this technology can achieve measurements far smaller than the width of a human hair. This makes the choice of interferometer manufacturers especially important for labs, factories, and research centers seeking dependable precision.

Understanding the Interferometer

Before looking into interferometer manufacturers, it helps to understand what an interferometer does. In everyday life, measuring something usually involves a ruler or a tape measure. These tools are fine for millimeters or centimeters, but when measurements reach the scale of nanometers – billionths of a meter – traditional tools no longer work.

An interferometer fills this gap. By using interference patterns created when two beams of light overlap, it can show minute changes in length, angle, or surface texture. This principle underpins countless applications in optics, engineering, astronomy, and materials science.

Because interferometers are sensitive to factors like vibration, temperature, and air currents, the quality of design and assembly offered by interferometer manufacturers can directly affect measurement reliability.

The Role of Interferometer Manufacturers in Precision Technology

Interferometer manufacturers are more than just producers of equipment. They are partners in innovation and quality control. These manufacturers design, build, and test instruments capable of meeting specific needs in research, industry, or production environments.

From selecting high-quality optical components to ensuring proper alignment and calibration, the expertise of interferometer manufacturers ensures that the final product can perform under real-world conditions. Their work directly impacts the ability of scientists and engineers to make breakthroughs or maintain high production standards.

When a research lab orders an interferometer, it’s not simply purchasing a device – it’s investing in a precision tool whose reliability depends on the skill of its maker. This is why the selection process for interferometer manufacturers is as critical as choosing the instrument itself.

Why Quality Matters in Interferometer Manufacturing

Every interferometer consists of sensitive optical and mechanical parts. Even the slightest flaw can introduce errors in measurement. High-quality interferometer manufacturers understand this and build their devices with extreme attention to detail.

They also take environmental factors into account. For instance, an interferometer used in a cleanroom may require special housings or materials to avoid contamination, while one used on a production floor might need vibration isolation. The best interferometer manufacturers design their instruments to maintain precision under these varied conditions.

This focus on quality protects users from costly downtime, inaccurate data, or repeated recalibration. In high-stakes fields like aerospace or semiconductor production, even a small error can translate into significant financial or safety risks.

Benefits of Working with Reliable Interferometer Manufacturers

Choosing the right interferometer manufacturers can bring many benefits, including:

-

Consistent, high-quality measurements over time.

-

Access to technical support and training for proper instrument use.

-

Confidence that equipment meets industry or regulatory standards.

These benefits extend beyond the initial purchase. Long-term partnerships with reputable interferometer manufacturers often lead to better maintenance services, upgrades, and advice on integrating new technologies.

Tips for Selecting the Right Interferometer Manufacturers

Finding the best partner for your needs takes some research. Here are a few tips:

-

Clearly define your measurement requirements before contacting a manufacturer.

-

Ask about calibration procedures and quality control standards.

-

Check whether they offer customization options for specialized applications.

By following these tips, organizations can choose interferometer manufacturers that align with their goals and ensure that their investment pays off in reliable, precise measurements.

Applications That Depend on Interferometers

Interferometers are used in a variety of fields, and the manufacturers who produce them cater to a wide range of applications. In manufacturing, they help verify the flatness of surfaces or measure the thickness of coatings. In research labs, interferometers can monitor vibrations, analyze optical components, or even measure the speed of light.

This diversity of applications means interferometer manufacturers must be versatile, offering products tailored to different industries while maintaining strict quality standards. Some focus on compact, portable systems, while others specialize in large, stationary instruments for highly controlled environments.

Trends Shaping the Future of Interferometer Manufacturers

The world of precision measurement is constantly evolving. New materials, faster production methods, and the demand for miniaturization are pushing interferometer manufacturers to innovate.

Emerging trends include the integration of digital technology and software into interferometers, allowing for automated data collection and analysis. Another development is the push toward user-friendly designs so that even non-specialists can operate complex instruments effectively.

Sustainability is also on the agenda. Many interferometer manufacturers are looking for ways to reduce waste, improve energy efficiency in production, and extend the lifespan of their products. These trends ensure that interferometers remain relevant and effective tools for the future.

The Impact of Interferometer Manufacturers on Industry and Research

Without skilled interferometer manufacturers, many of today’s technological achievements would not be possible. They provide the tools that scientists use to test theories, engineers rely on to maintain quality, and manufacturers need to ensure products meet strict specifications.

This partnership between instrument makers and users drives progress across multiple fields. As demand for higher precision grows, so does the need for interferometer manufacturers who can deliver reliable solutions. In this way, the manufacturers become silent partners in innovation, enabling discoveries and improvements that benefit society as a whole.

Conclusion

An interferometer is an essential instrument for measuring the tiniest details in science and engineering. But behind every effective interferometer is the expertise and dedication of skilled interferometer manufacturers. By understanding what these manufacturers do and why their quality matters, professionals can make informed choices that support their work.

Whether you’re a researcher, engineer, or production manager, knowing how to select the right interferometer manufacturers will help you get the most out of your precision tools and ensure your measurements stand up to the highest standards.

Learn how interferometer manufacturers shape precision measurement, what an interferometer does, and tips for choosing reliable partners for your needs.

FAQs

Q1: What is an interferometer used for?

It is used to measure extremely small distances, vibrations, or changes in surfaces with exceptional accuracy.

Q2: Why are interferometer manufacturers important?

They design and build precision instruments whose performance directly affects the reliability of scientific and industrial measurements.

Q3: How can I choose the right interferometer manufacturers?

Evaluate your measurement needs, check the manufacturer’s quality standards, and ask about calibration, customization, and support services.

Q4: Do all interferometer manufacturers offer the same types of instruments?

No. Some specialize in certain applications or designs, so it’s important to select one whose products match your specific requirements.