In industrial environments, electrical safety is a top priority, and industrial circuit breakers are critical components that protect complex electrical systems from overloads and short circuits. These devices are designed to handle high currents and safeguard equipment and personnel from potential hazards. Meanwhile, residential circuit breakers are tailored for home use, focusing on protecting household circuits and appliances. Understanding the differences and applications of these breakers is essential for both facility managers and electricians.

What Are Industrial Circuit Breakers?

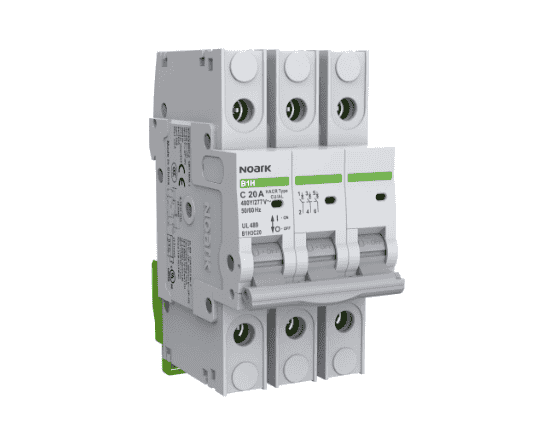

Industrial circuit breakers are sophisticated devices designed to automatically interrupt electrical flow in the event of a fault. Their main purpose is to prevent damage to equipment, reduce the risk of fire, and protect personnel from electrical hazards. Unlike residential breakers, industrial breakers are built to withstand much higher currents and demanding conditions typically found in factories, manufacturing plants, and large commercial facilities.

Key Features of Industrial Circuit Breakers

-

High Interrupting Capacity: Capable of handling large fault currents without failing.

-

Adjustable Trip Settings: Allows customization for specific industrial applications.

-

Durable Construction: Designed to endure harsh industrial environments.

-

Enhanced Safety Mechanisms: Provides additional protections such as ground fault detection and overload alarms.

These features ensure that industrial circuit breakers are reliable and efficient in protecting large-scale electrical systems.

How Industrial Circuit Breakers Work

Industrial circuit breakers operate by monitoring the flow of electricity. When an overload or short circuit occurs, the breaker trips, cutting off the electrical supply to prevent damage. This is achieved through thermal, magnetic, or electronic trip mechanisms, depending on the design.

Thermal trip mechanisms use a bimetallic strip that bends when heated by excess current, triggering the breaker to open. Magnetic trips employ an electromagnet that activates instantly under high currents. Electronic trips provide more precise control and are often used in advanced industrial applications where system sensitivity and timing are critical.

By interrupting the current at the right moment, industrial circuit breakers protect both the machinery and the personnel working with it.

Differences Between Industrial and Residential Circuit Breakers

While both types of circuit breakers serve to prevent electrical hazards, their design and applications are quite different.

Industrial circuit breakers are rated for higher currents and designed to manage complex electrical networks with heavy machinery and high load demands. They offer adjustable settings, high interrupting capacities, and more robust construction to ensure safety and reliability in harsh environments.

In contrast, residential circuit breakers are designed for household circuits, typically handling 15–20 amps. They protect common appliances and wiring from overloads and short circuits but are not suitable for high-capacity industrial equipment. Understanding these differences is crucial when selecting a breaker for a specific application.

Types of Industrial Circuit Breakers

Industrial circuit breakers come in several types, each suited for specific applications:

Molded Case Circuit Breakers (MCCBs): These are versatile breakers used in a wide range of industrial settings. They allow adjustable trip settings and handle a broad spectrum of current ratings.

Air Circuit Breakers (ACBs): Designed for high-current applications, ACBs use air to extinguish arcs and are often installed in switchgear assemblies.

Vacuum Circuit Breakers (VCBs): VCBs use vacuum as the arc-quenching medium, offering compact, maintenance-free operation for medium-voltage systems.

Sulfur Hexafluoride (SF₆) Circuit Breakers: These are used in high-voltage applications where SF₆ gas provides excellent insulation and arc-quenching properties.

Choosing the right type of breaker depends on the system’s voltage, current, and operational environment.

Selecting the Right Industrial Circuit Breaker

Selecting the appropriate industrial circuit breaker is critical for safety and efficiency. Several factors must be considered:

-

Current Rating: The breaker must handle the maximum expected current without tripping unnecessarily.

-

Interrupting Capacity: It must safely interrupt the maximum fault current in the system.

-

Environmental Conditions: Temperature, humidity, and exposure to dust or chemicals can impact performance.

-

Compliance: Ensure the breaker meets industry standards and regulations.

By carefully evaluating these factors, industries can choose a breaker that offers optimal protection and reliable operation.

Maintenance and Testing

Maintaining industrial circuit breakers is essential for ensuring their longevity and reliability. Regular inspections can prevent unexpected failures and costly downtime.

Visual inspections help identify signs of wear, overheating, or corrosion. Cleaning is crucial to remove dust and debris that could interfere with operation. Mechanical components should be lubricated to reduce wear and ensure smooth functionality.

Testing is equally important. Trip testing ensures the breaker operates at the correct current thresholds. Insulation resistance tests verify the integrity of internal insulation, while contact resistance tests detect any degradation that could affect performance. Routine maintenance and testing extend the life of the breaker and maintain safety standards.

Common Issues With Industrial Circuit Breakers

Even well-maintained breakers can face issues. Overheating may occur due to prolonged high loads or poor ventilation. Nuisance tripping—frequent, unnecessary trips—can disrupt operations and is often caused by incorrect settings, transient faults, or faulty components. Mechanical failures can result from wear and tear, preventing the breaker from operating correctly during a fault. Recognizing and addressing these issues promptly is vital to maintaining operational safety and efficiency.

Benefits of Using Industrial Circuit Breakers

The benefits of properly selected and maintained industrial circuit breakers are significant:

-

Enhanced Safety: Protects personnel and equipment from electrical faults.

-

Reduced Downtime: Prevents damage that could halt production or operations.

-

Energy Efficiency: Maintains consistent electrical performance, avoiding wasted energy.

-

Longevity of Equipment: Minimizes wear on machines by preventing electrical surges.

These advantages demonstrate why investing in quality industrial circuit breakers is essential for industrial facilities.

Practical Applications

Industrial circuit breakers are used in diverse industries, from manufacturing and processing plants to commercial buildings and power distribution networks. They safeguard critical machinery such as motors, pumps, compressors, and heavy-duty production lines. In every application, the breaker ensures that equipment operates within safe parameters, preventing catastrophic failures and keeping operations running smoothly.

Conclusion

Industrial circuit breakers are indispensable for safeguarding electrical systems in demanding environments. Their ability to detect and interrupt electrical faults ensures safety, prevents damage, and maintains the reliability of industrial operations. By understanding the types, features, selection criteria, and maintenance practices associated with these devices, businesses can optimize their electrical infrastructure and achieve long-term operational efficiency.

FAQs

Q1: What is the main function of an industrial circuit breaker?

Industrial circuit breakers protect electrical systems by interrupting power during overloads, short circuits, or other faults.

Q2: How do industrial circuit breakers differ from residential circuit breakers?

Industrial breakers handle higher currents, have adjustable trip settings, and are built for demanding environments, while residential breakers protect household circuits.

Q3: What types of industrial circuit breakers are commonly used?

MCCBs, ACBs, VCBs, and SF₆ breakers are common, each suited for different voltages, currents, and industrial applications.

Q4: Why is regular maintenance important for industrial circuit breakers?

Maintenance ensures reliable operation, prevents unexpected failures, and extends the lifespan of the breaker and the connected equipment.